Parallel Hybrid Types

There are a few different approaches to connecting the motor/generator to the engine drive chain.

The main configurations are external and flywheel connection.

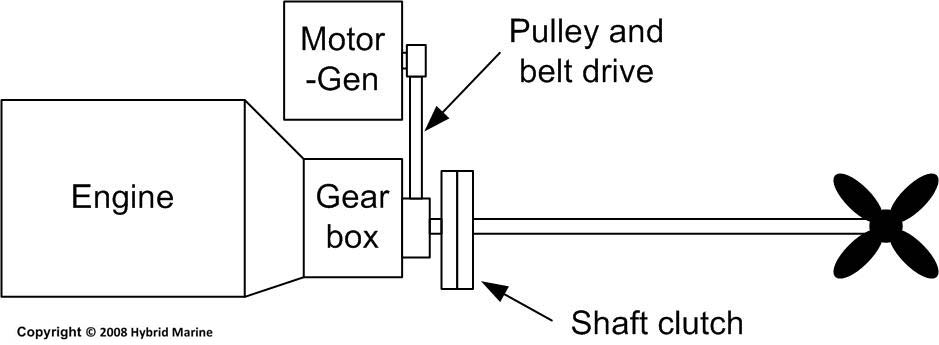

External Motor Parallel Hybrid

|

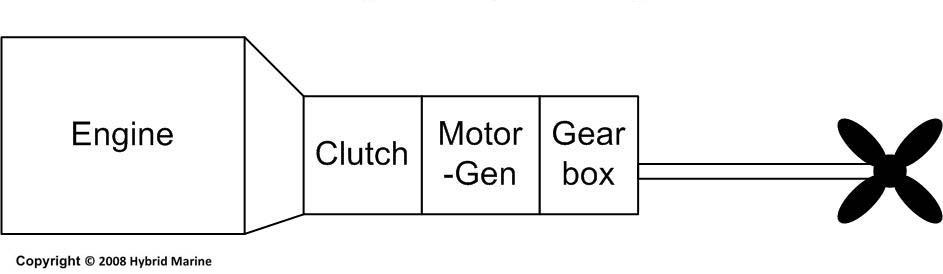

Flywheel Parallel Hybrid

|

Summary

Here is a comparison of the two approaches

|

External Motor

|

Flywheel Mounted

|

||

| Cooling | Not in direct contact with the engine so cooling is a little easier. Liquid cooled, brushless motor used with its own cooling circuit. | In close proximity to engine requires the bell housing to have a cooling jacket or may be air cooled | |

| Servicing | Easy to remove, service and replace the motor. Engine is not disabled if motor is removed. Shaft clutch accessible and can easily be locked together if it fails. | Gearbox need to be removed to gain access to motor/generator and clutch. Depending on the installation this may require the engine to be removed from the craft. | |

| Reliability | Failure of hybrid component does not disable the engine. Shaft clutch (if fitted) can be easily locked together if there is a problem | No easy access to motor/generator and it can not be disconnected if it fails. Clutch between engine and motor/generator is a weak point, if it fails then engine drive is disabled and can not be rectified easily. | |

| Flexibility | The pulley/belt drive gives great flexibility. Drive ratio of the motor can be set independently from the gearbox. This allows matching of the motor to a wide range of engines. Adjustment in-service is simply a change of external pulley size. | Drive ratio fixed to that of the gearbox. This generally needs the motor to have more torque to compensate and increases cost. Field weakening can be used to extend speed range but reduces motor efficiency. No in-service adjustment possible. | |

| Future proofing | As motor technology improves and becomes more cost effective the motor can easily be upgraded. | Much more difficult to upgrade the motor. | |

| Drive belt | The toothed drive belt and pulley arrangement is very flexible and low loss (typically 1% t0 2%). Used in such diverse applications as stone crushing machines to replacing chains in performance motorbikes. If you hit a solid object this can break a belt. Such a collision can damage an engine mount or break a gearbox damper plate if on engine drive. So having a belt break first can save more expensive components and will not disable the engine. It only takes a short time to replace a broken belt at low cost. | Not applicable |